OUR SERVICES

At DGL Engineering, we offer a diverse range of high-quality services to meet your engineering and manufacturing needs. From CAD design and 3D printing for rapid prototyping and custom parts, to milling and turning for precise, complex machining, we are equipped to handle everything from one-off projects to small production runs. Our focus is on delivering tailored solutions that combine innovation, precision, and cost-effectiveness, ensuring that each project, no matter the size, is executed to the highest standards.

-

Whether you need a custom-made part, a replacement component, jigs and fixtures, or just want to trial an idea — DGL Engineering is your one-stop solution.

We specialise in low-volume, precision machining and 3D printing to support everything from personal projects to industrial applications. Whether you’re an engineer with a rough sketch, a hobbyist with a broken part, or a business looking to streamline a process with a new fixture — we can help bring your ideas to life.

Our bespoke service is ideal for:

Custom or discontinued replacement parts

Proof-of-concept components

Jigs, fixtures, and tooling for production use

One-off prototypes for form, fit, and function testing

Rapid development of short-run items

We work closely with you at every stage — from design guidance and material selection to machining and finishing — ensuring your project is delivered to spec and on time. No minimum order quantity, and no red tape — just straightforward, practical engineering support.

-

Got a broken or worn-out part? Before you replace it, let us take a look. At DGL Engineering, we offer practical repair and refurbishment services to help get your equipment back up and running — quickly and cost-effectively.

We can assess and restore a wide range of components, including:

Damaged or worn mechanical parts

Shafts, housings, and brackets

Thread repairs and re-machining

Custom bushings or sleeves for worn fits

3D printed replacement parts (where suitable)

Whether it’s a one-off breakdown or part of ongoing maintenance, we’ll work with you to find the best solution — repair, modify, or remake. With flexible turnaround times and a no-fuss approach, we’re here to keep your downtime to a minimum.

-

Need a handful of parts — not hundreds or thousands? DGL Engineering is set up for small batch production, combining the precision of CNC machining with the flexibility of traditional manual methods. This means we can take on a wide range of jobs efficiently, even when volumes are low.

Ideal for:

Startups and product developers

Replacement parts in limited quantities

Custom fittings and components

Short-run manufacturing or trial batches

Whether it's a one-off item or a run of 5, 10, or 50 parts, we can tailor the process to suit your needs — from manual turning and milling for simpler jobs, to CNC machining for repeatable accuracy and tight tolerances.

We also offer 3D printing for non-metal components or early-stage prototypes, giving you even more flexibility when it comes to materials, cost, and turnaround time.

-

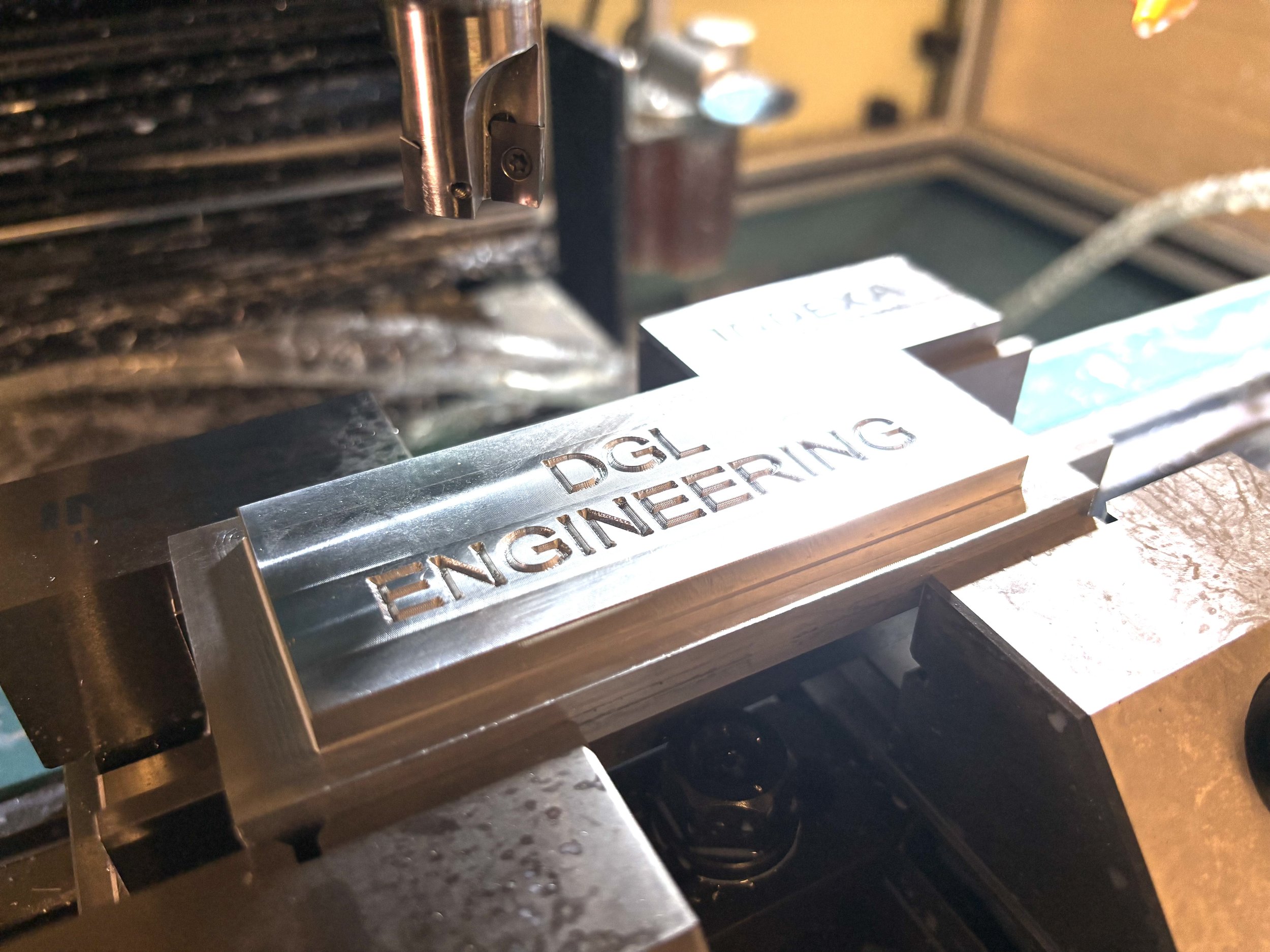

Milling is a versatile and precise machining process used to remove material from a workpiece using cutters. At DGL Engineering, our milling service involves the use of advanced milling machines to produce complex and accurate parts from a wide range of materials, including metals, plastics, and composites.

Our milling capabilities include traditional milling, allowing us to handle projects of varying sizes and complexity. Whether you're looking for one-off custom parts, repeated production runs, modifications, or repairs, we ensure that every piece meets your specific requirements with high precision and efficiency.

Key Features of Our Milling Service:

Precision: Achieving tight tolerances to ensure the accuracy of each part.

Versatility: Capable of producing a wide variety of parts, from simple components to intricate designs.

Materials: We work with a broad range of materials, including aluminum, steel, brass, plastics, and more.

Custom Solutions: Tailored to your exact specifications, including complex geometries and prototypes.

Prototyping & Production: Whether you need a single prototype or a batch of parts, we can accommodate both needs.

Our milling service is ideal for creating components that require high precision, complex shapes, and tight tolerances. Whether you're in need of engineering prototypes, spare parts, or custom machinery components, we have the expertise to bring your designs to life with efficiency and quality.

-

Turning is a machining process that involves rotating a workpiece while a cutting tool is applied to shape it into cylindrical or conical forms. At DGL Engineering, our turning service is designed to provide high-precision, custom solutions for a wide range of applications. We use manual turning techniques to produce accurate and reliable parts.

Key Features of Our Turning Service:

Precision and Accuracy: We specialize in achieving tight tolerances, ensuring every part meets exact specifications.

Versatility: Capable of machining various shapes, from simple cylinders to more complex profiles such as threads, grooves, and tapers.

Materials: We can machine a variety of materials, including metals (aluminum, steel, brass), plastics, and other composites.

Custom Solutions: We offer tailored solutions for one-off components, low-volume production, and part modifications.

Efficiency: Whether you need a single custom piece or a batch of parts, our service is designed to optimize both quality and delivery time.

Our turning service is perfect for producing parts that require cylindrical shapes, precision threading, and other features such as knurling or boring. Whether you need components for machinery, automotive, or prototyping purposes, we ensure every part is crafted to your specifications with the utmost care and accuracy.

-

3D printing, or additive manufacturing, is a process where material is added layer by layer to build a part or prototype based on a digital 3D model. At DGL Engineering, our 3D printing service allows for rapid prototyping, custom parts, and complex geometries that traditional manufacturing methods may struggle to achieve. We use advanced 3D printing technologies to provide cost-effective and efficient solutions, particularly for low-volume production, rapid iteration, and customized designs.

Key Features of Our 3D Printing Service:

Rapid Prototyping: Quickly create prototypes to test designs, reducing development time and costs.

Complex Geometries: Capable of producing intricate shapes, structures, and features that are challenging for conventional methods.

Material Variety: We work with a range of materials, including common thermoplastics (PLA, ABS, PETG)

Custom Solutions: Ideal for small batches, one-off parts, and unique designs that require a high level of customization.

Cost-Effective: 3D printing is an economical solution for low-volume production, prototyping, and tooling.

Our 3D printing service is perfect for creating lightweight, durable, and complex components with minimal waste. Whether you're in need of prototypes for design testing, custom parts for machinery, or short-run production, we provide fast, reliable, and high-quality results.

-

Computer-Aided Design (CAD) is a digital tool used to create, modify, analyze, and optimize designs. At DGL Engineering, our CAD service allows for precise, detailed, and accurate design work, providing the foundation for all our machining, prototyping, and 3D printing processes. Whether you need 2D drawings, 3D models, or assemblies, our CAD service ensures your ideas are brought to life with the highest level of precision and functionality.

Key Features of Our CAD Service:

Custom Design: Tailored to your specific requirements, we create detailed models and technical drawings for new products, modifications, or improvements to existing designs.

3D Modeling: We specialize in creating 3D models that provide a comprehensive view of your design.

Prototyping Support: CAD models serve as the basis for prototypes, ensuring that designs are accurate and manufacturable before production begins.

Compatibility: Our CAD files can be exported in various formats, ensuring compatibility with a range of manufacturing processes, including 3D printing files.

Collaboration: We work closely with clients to refine and optimize designs, ensuring functionality, cost-efficiency, and manufacturability.

Our CAD service is ideal for businesses looking to develop new products, improve existing designs, or prepare for manufacturing processes. By utilizing cutting-edge CAD tools, we streamline the design process, reduce errors, and improve the overall efficiency of your project. Whether you're in need of conceptual designs, technical drawings, or ready-to-manufacture models, our CAD service provides the precision and expertise to bring your vision to life.